What makes the difference?

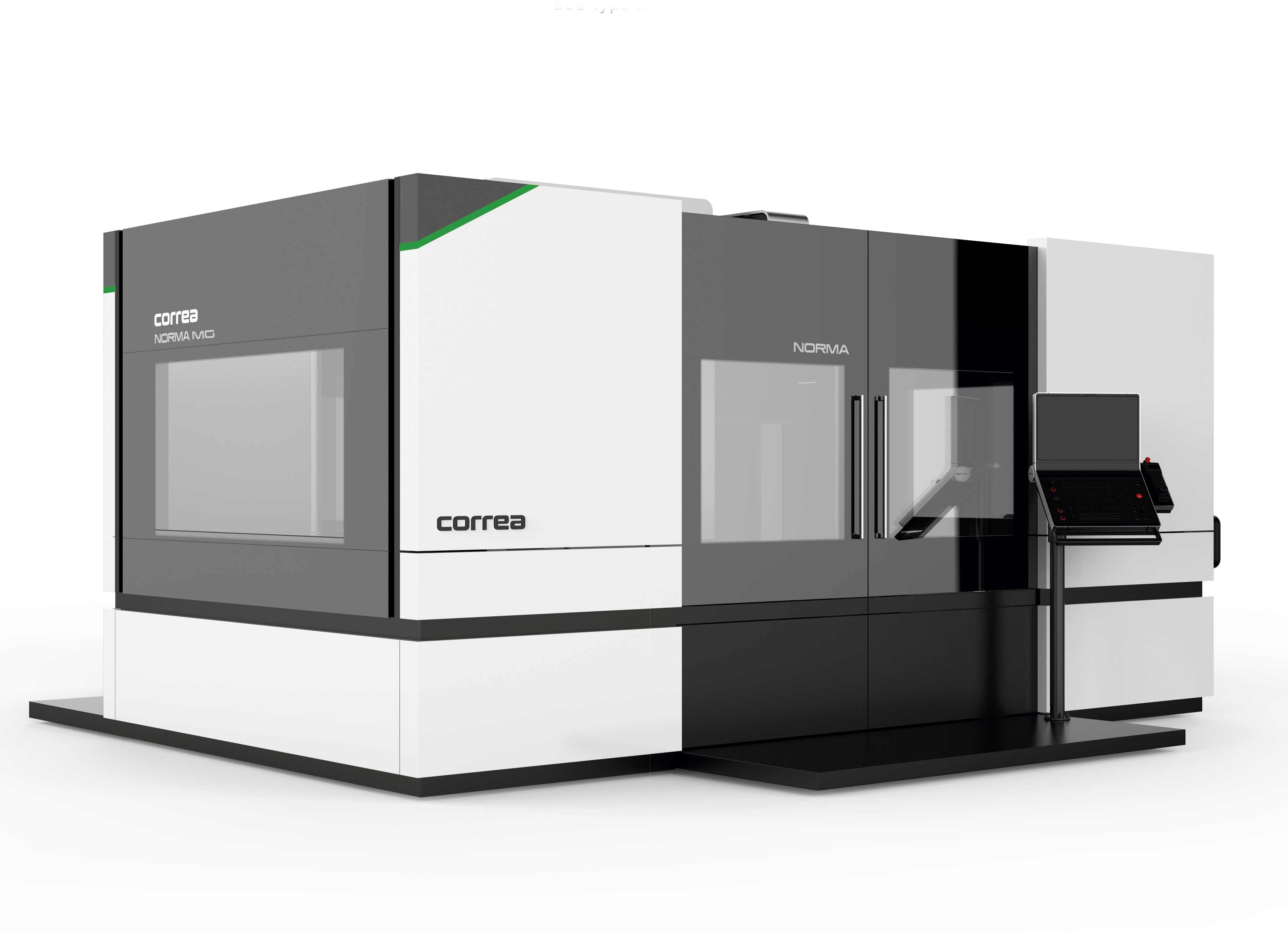

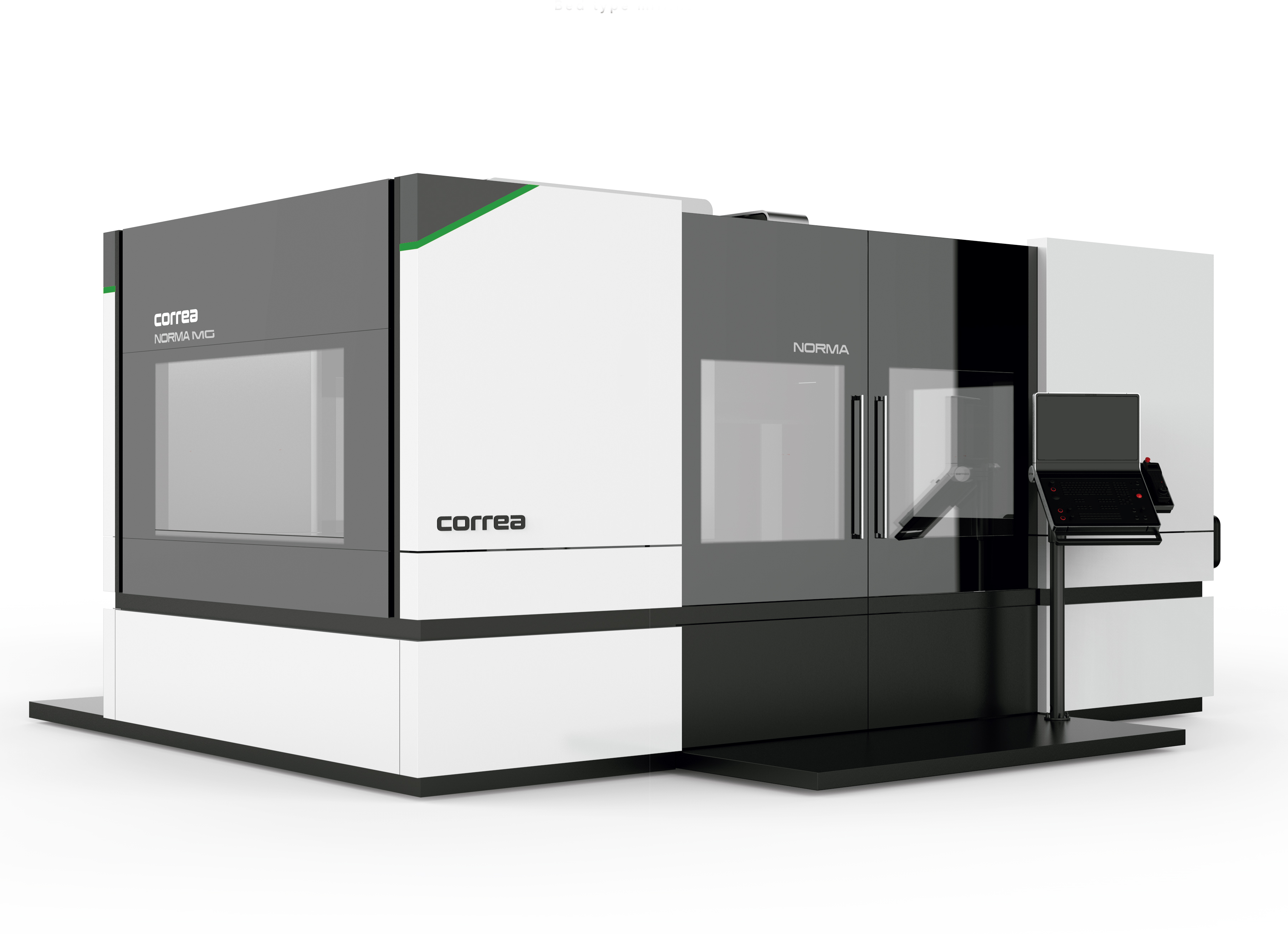

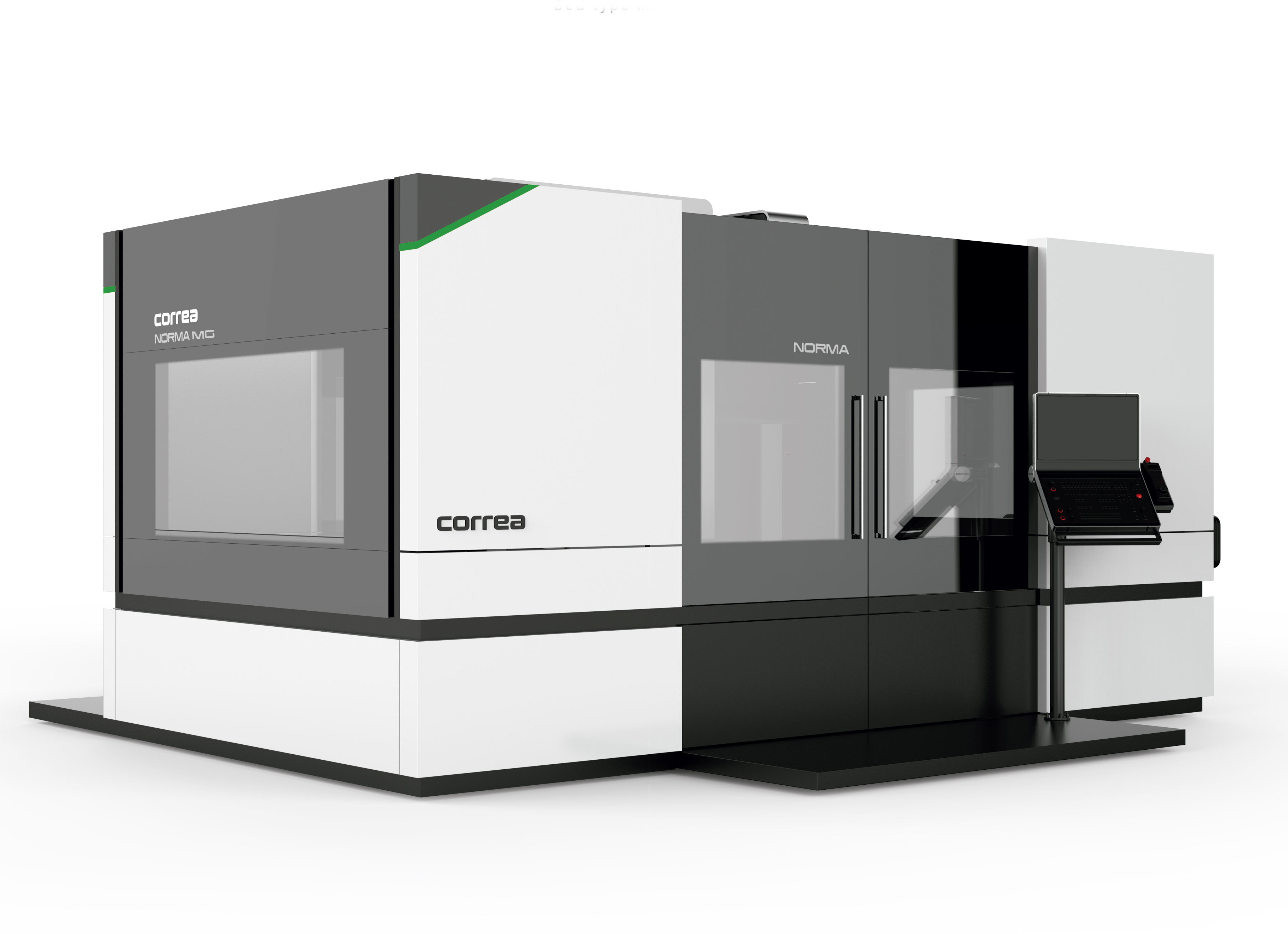

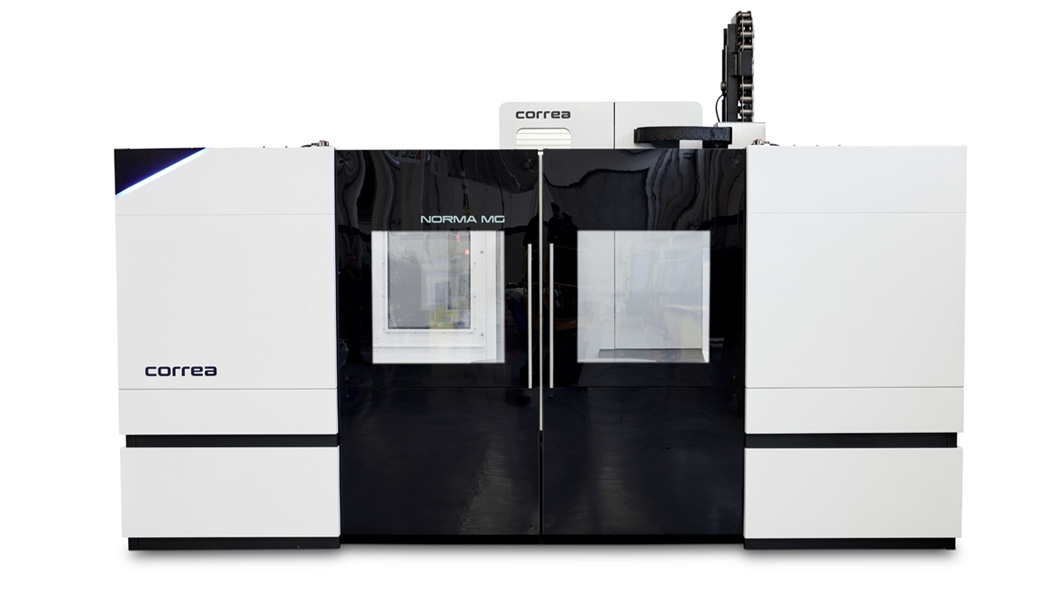

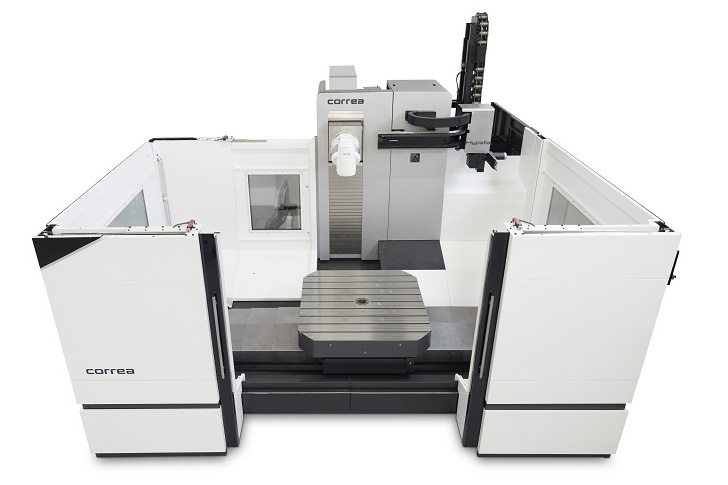

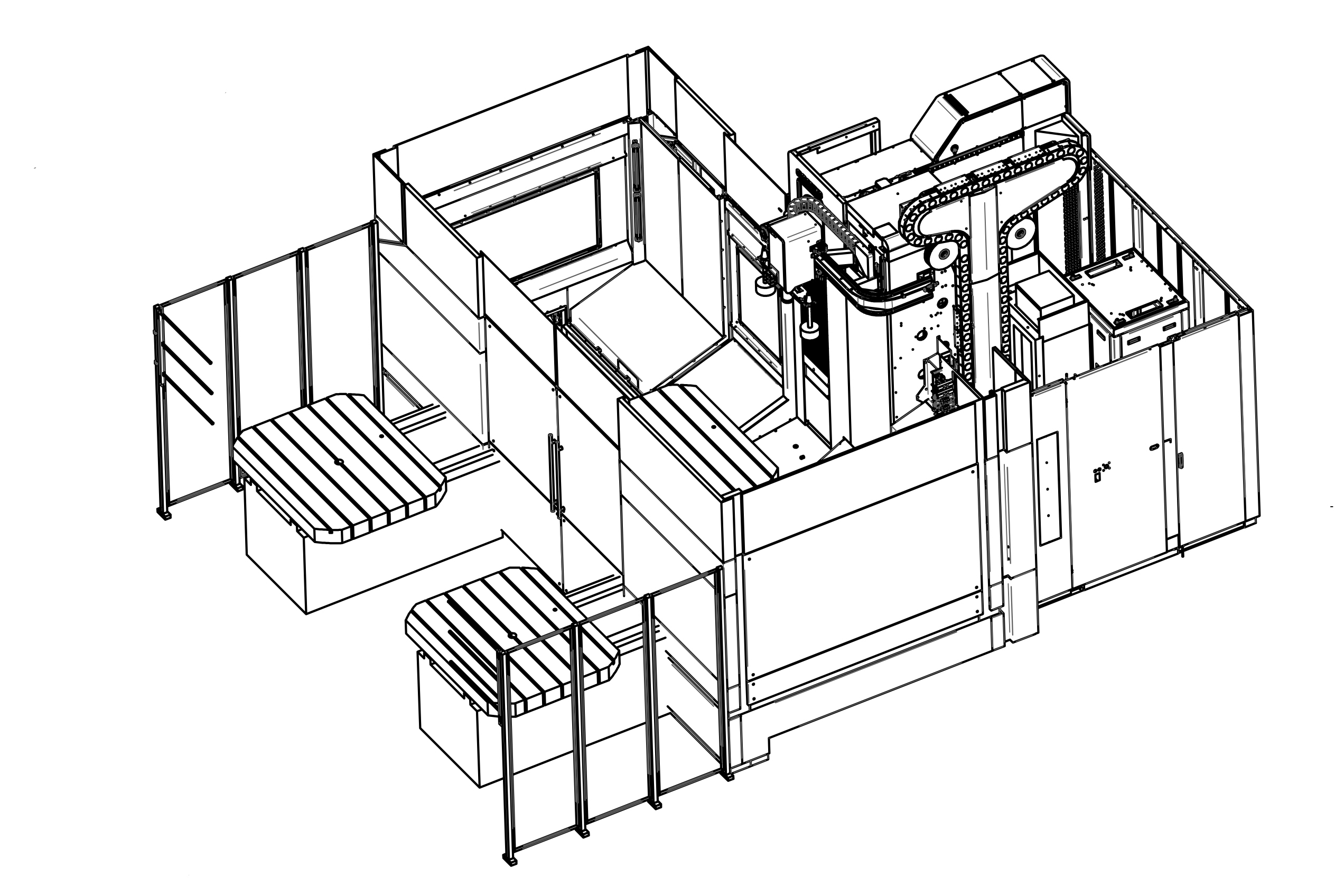

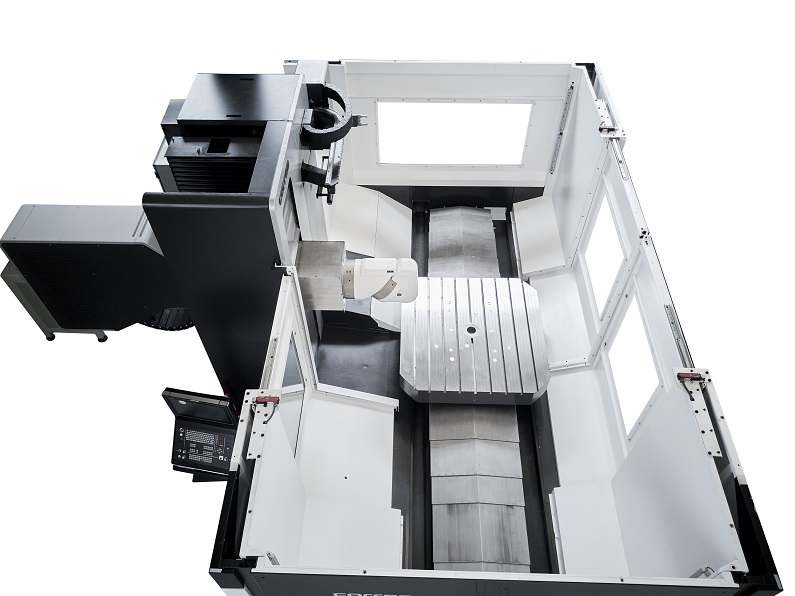

Bed type milling machine NORMA MG with lateral ram offers robustness thanks to its ram guiding system in L. This machine has different options of rotary and turning table which provides great flexibility to perform several machining operations. The milling machine has 4+2 axes to offer high flexibility maintaining robustness and precision of Correa indexed milling heads with rotation every 0.02º, patented by Nicolás Correa.

-

![Eco Design]()

![Eco Design]()

Eco Design

Stand-by function and Auto Switch off function, saving 20% of the total energy machine consumption.

-

![High Feed Rates]()

![High Feed Rates]()

High Feed Rates

30–40 m/min in X, Y and Z axes, thanks to its V-Shaped linear guide-ways in all axes.

-

![High Geometrical Precision]()

![High Geometrical Precision]()

High Geometrical Precision

High machining capacity + geometrical stability over time.

-

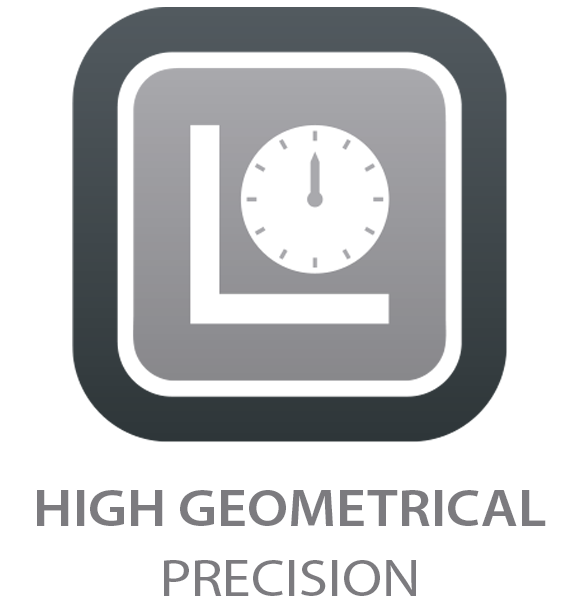

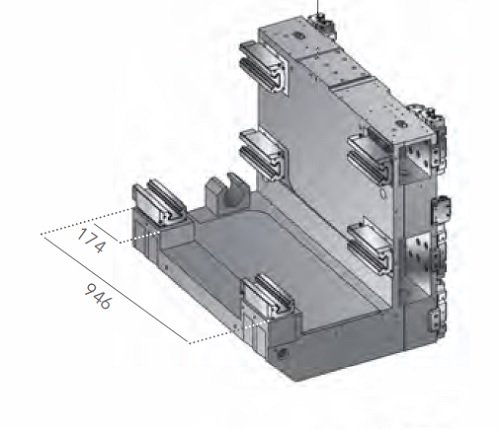

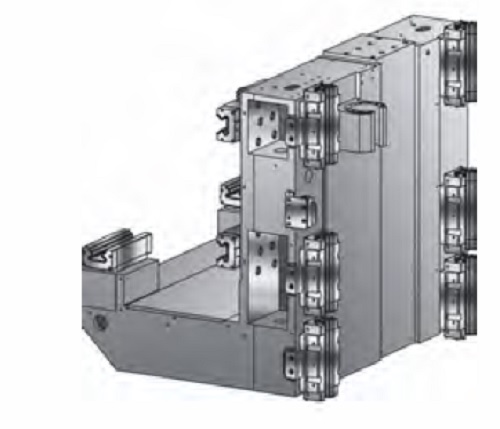

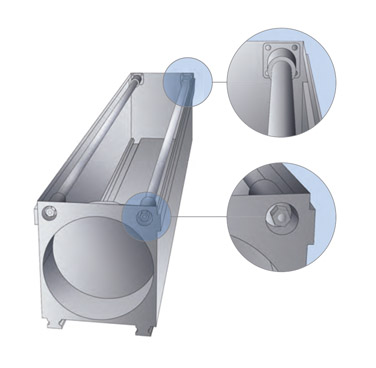

![L Guide-way System Configuration]()

![L Guide-way System Configuration]()

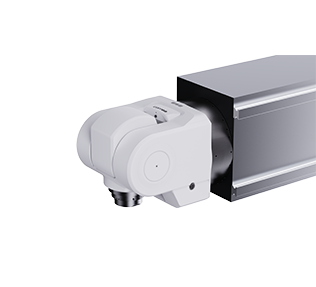

L Guide-way System Configuration

L-shaped guide system:

- Greater rigidity and stability during machining.

- Greater geometrical precision.

- Less ram droop effect.

6 vertical movementsliders ensuring good machine behaviour

![L Guide-way System Configuration]()

L Guide-way System Configuration

L-shaped guide system:

- Greater rigidity and stability during machining.

- Greater geometrical precision.

- Less ram droop effect.

6 vertical movementsliders ensuring good machine behaviour

-

![Mechanical Compensation System]()

![Mechanical Compensation System]()

Mechanical Compensation System

Pulling bars for fine tuning adjustment of ram droop effect.

-

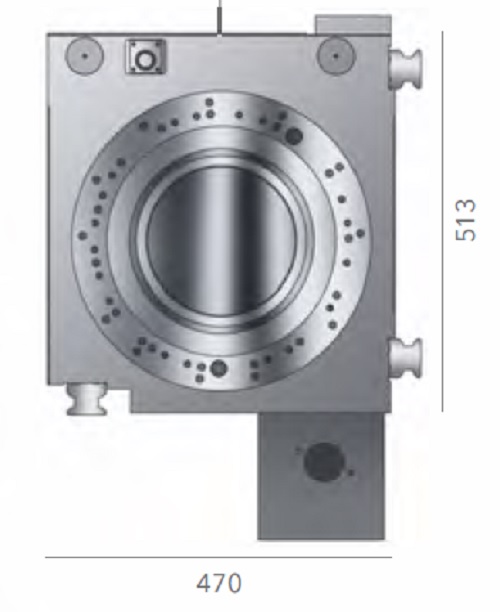

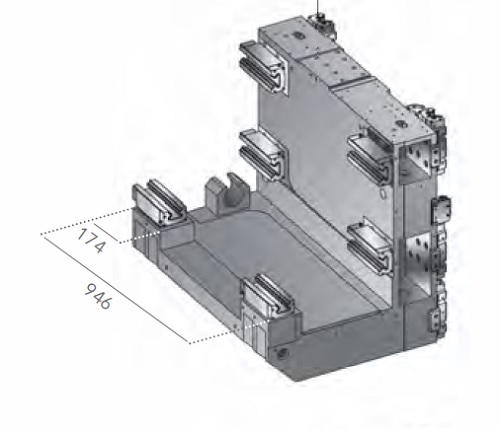

![Oversized Structural Elements]()

![Oversized Structural Elements]()

Oversized Structural Elements

The largest cross-sections on the market.

High machining capacity + geometrical stability over time.

![Oversized Structural Elements]()

Oversized Structural Elements

The largest cross-sections on the market.

High machining capacity + geometrical stability over time.

-

![Multi-Function Operation]()

![Multi Fuction Operation]()

Multi Fuction Operation

- Rotary table for circular milling operation.

- Maximum turning diameter of 2500 mm.

- Rotary table completely integrated in the machine’s kinematics to work in 4+2 axes.

- Turning table for a diameter up to 2000 mm

-

![Machine Dynamic Adjustment]()

![Machine Dynamic Adjustment]()

Machine Dynamic Adjustment

Dynamic performance parametrizable in accordance with:

- ROUGHING OPERATION

- FINISHING OPERATION

Technical specifications

| 25 | 35 | ||||||

|---|---|---|---|---|---|---|---|

| Table | |||||||

| Surface | mm | 1,250 x 1,250 / 1,600 x 1,250 / 1,600 x 1,600 / 2,000 x 1,600 | |||||

| Maximum load on the table | Tm | 7 - 10 | |||||

| Traverses | |||||||

| Longitudinal | X mm | 2,500 | 3,500 | ||||

| Cross | Y mm | 1,250 / 1,500 | |||||

| Vertical | Z mm | 1,500 / 2,000 | |||||

| Feeds | |||||||

| Maximum | X m/min | 30 | |||||

| Y m/min | 30 | ||||||

| Z m/min | 30 | ||||||

| Spindle specifications | |||||||

| Taper | ISO-50 Big Plus / HSK-100 | ||||||

| Programmable speed | rpm | 4,000 / 6,000 / 10,000 | |||||

| Maximum power | kW | 24 - 33 - 30 | |||||

| Maximum torque | Nm | 840 - 990 - 620 | |||||

Heads

UAD Technology

Universal and orthogonal indexing milling heads unique in the market. Patented technology allowing rotation every 0,02º.

5 axes Technology.

2 axes contouring head "Twist" type with built in electrospindle or spindle geared transmission.

Are you interested in our heads?

Standard and optional equipment

Standard equipment

- Automatic Universal Head

- Integrated Rotary Table

- Numerical control Heidenhain or Siemens

- Portable handwheel

- Air-conditioned electrical cabinet

- Linear guides in the X, Y and Z axes

- Lamp in the working area

- Gearbox

- Hydraulic group

- Linear scales in all axes

- External Coolant with adjustable nozzles in the head

- Perimeter fence

- Direct Tele-service

- VIXION 4.0

Optional equipment

- Other heads

- Probes of measurement, tools and parts

- Automatic charger for 30, 40 and 60 tools

- Pick up station for 8 tools

- Air or oil cleaning gun with motor pump

- Centrifugal filter in cutting fluid tank

- Chip conveyors

- Integral guarding

- Basic guarding

- Coolant through spindle to high and medium pressure

- Integrated turning plate

- Automatic pallet changer

- Integrated turning table

- Automatic pallet changer