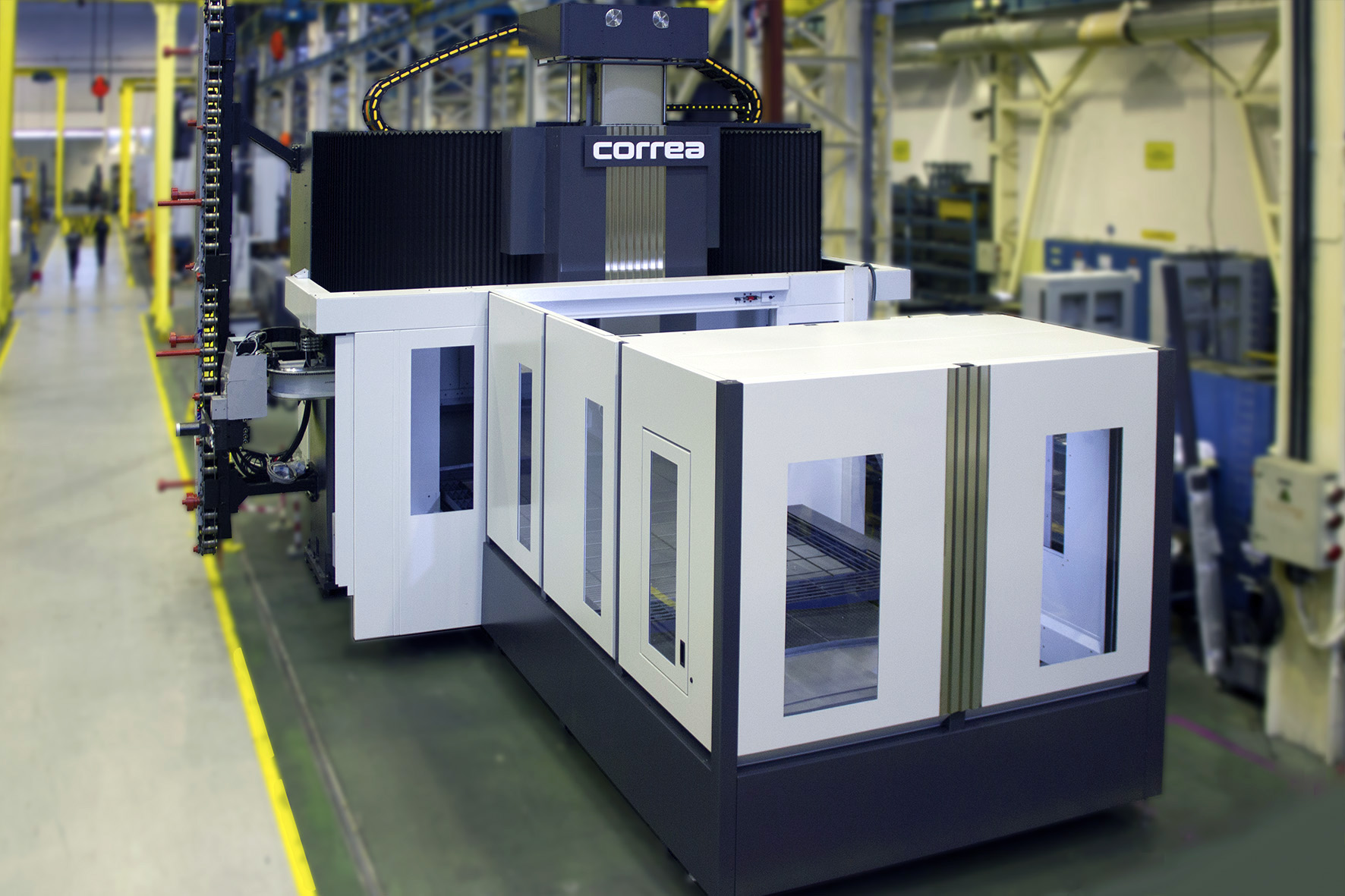

Crest Engineering purchased a Correa milling machine for the manufacturing of components for the aerospace industry

As part of the Hyde Group, Crest Engineering is heavily involved in precision machining of aerospace parts, primarily manufacturing engine casings and gearboxes for aircraft. Gareth Hunt from Crest Engineering explains that they were looking for a machine for a specific component, “the parts need to be machined to a high level of precision and the Correa Fox has thermal compensation throughout the machine area and not just on the spindle and this was a massive factor in our purchasing decision. In the UK, the climate can change daily, so having a thermally stable machine tool was a crucial factor for us”.

Referring to the capacity of the machine that has an impressive 4 by 3 by 1 metre in the X, Y and Z-axes, Mr Hunt continues: “The selection of a machine with such a large bed has an element of future-proofing the business […]. Our operators claim the machine is the best one we have in the factory and I have to absolutely agree with that sentiment.”

Read the full article on MTD CNC Magazine: https://mtdcnc.com/magazines/dts-uk-ltd/subcontractor-on-crest-of-a-wave-with-dts